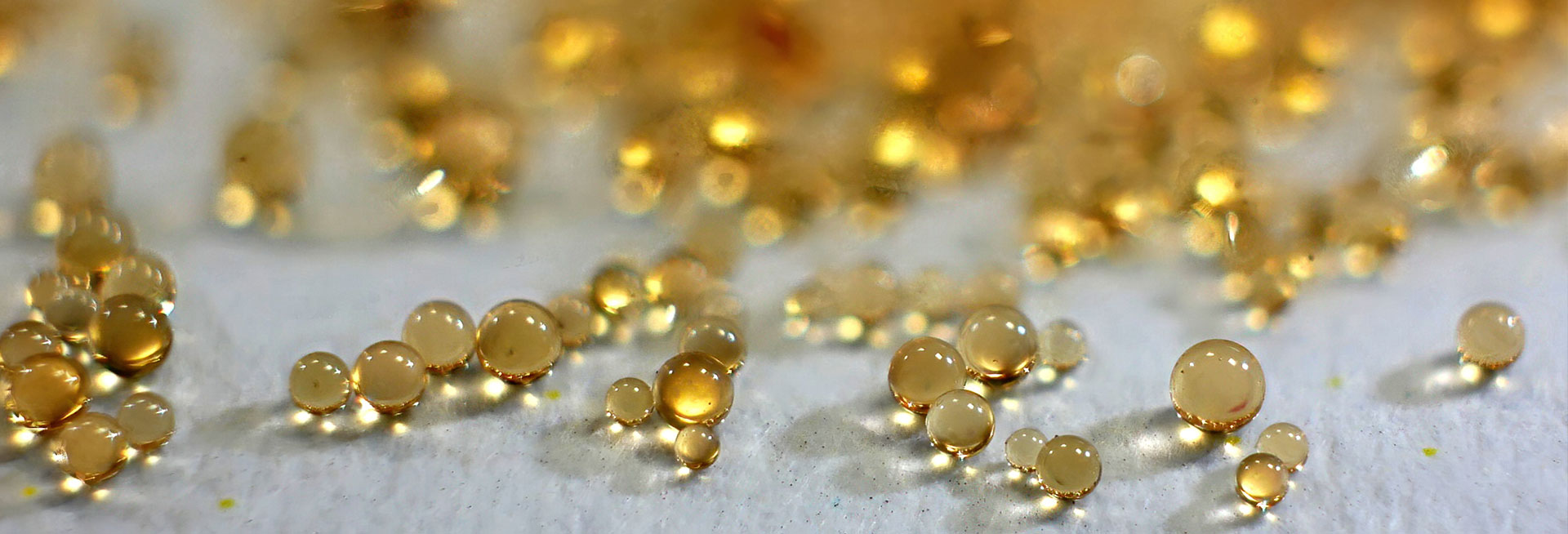

Discover the cutting-edge techniques of hydrometallurgy for extractive metallurgy at Glorinda. Our comprehensive approach spans leaching, solution concentration and purification, as well as metal or metal compound recovery. In the crucial phase of solution concentration, Glorinda employs advanced ion exchange technologies, leveraging cation, anion, chelating ion exchange resins, and adsorbent resins.

Our proprietary technology facilitates the exchange of cations and anions within the solution, allowing for the enrichment of metals, ideal for subsequent recovery, reuse, or efficient removal and disposal. This groundbreaking approach is a cornerstone in metals resource recycling and the high-purity metals impurity removal process.

Glorinda specializes in utilizing ion exchange resins to separate, concentrate, purify, and extract a spectrum of metals, including uranium, vanadium, tungsten, molybdenum, rare earth elements, gold, and silver from various ores.

Glorinda’s Achievements:

Our expertise extends to diverse applications, such as gallium recovery in the alumina industry, lithium carbonate recovery from saline lake bittern, scandium and zinc recovery, cobalt removal from nickel sulfate solutions, and extraction of precious metals like gold, silver, platinum, palladium, and rhodium.

Experience Glorinda's innovation in hydrometallurgy and mining, offering solutions for metal oxide extraction, removal of impurities in electrolyte solutions, and recovery processes across various industries. Trust Glorinda for sustainable, efficient, and economically impactful solutions in metals processing. In Brief, Our Processes Encompass:

| Gallium-Ga | Lithium-Li, | Nickel-Ni, | Copper-Cu, |

| Vanadium-V, | Rhenium-Rh, | Scandium-Sc, | Iron-Fe, |

| Cobalt-Co | Boron-B | Mercury-Hg | gold-Au |

| platinum-Pt | palladium-Pd | Uranium-U |