In the industrial landscape, the pervasive use of chemical products has led to an influx of organic pollutants into the atmosphere, predominantly low-boiling, volatile organic compounds (VOCs). These airborne gases pose risks, causing irritation to the human senses and potential harm to internal organs.

Glorinda, at the forefront of environmental innovation, introduces a sophisticated approach to VOCs treatment—Adsorption Technique. Our proprietary resin adsorption technology not only ensures compliance with emission standards but also facilitates the recovery of solvents, encompassing alkanes, halogenated hydrocarbons, aromatic hydrocarbons, low-carbon alcohols, ketones, esters, and various organic matters.

Key Features of Glorinda’s Adsorption Technology:

- Tailored Efficiency

-

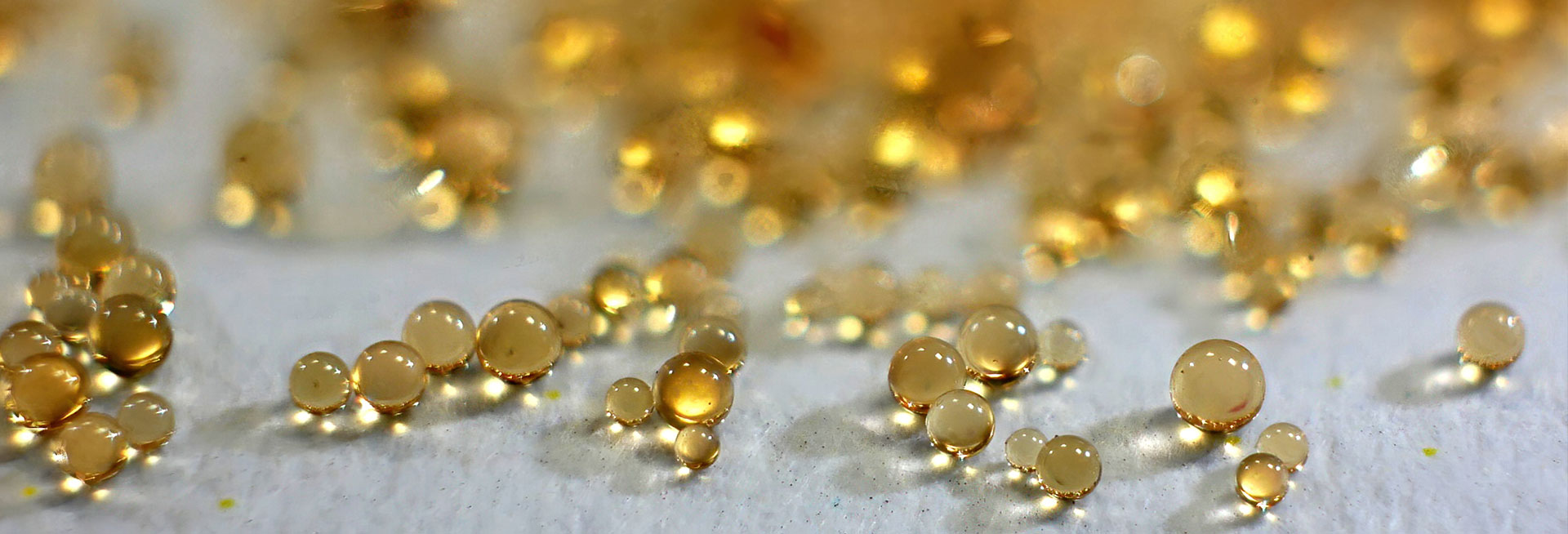

Specially designed macroporous polymer adsorption resin exhibits uniform pore size, high specific surface area, and robust strength, ensuring precise adsorption, recovery, and compliance with gas emission regulations.

- Versatility

-

Adaptable to diverse industries and systems, ranging from small-scale equipment to comprehensive waste gas treatment systems. Flexible collaboration to meet specific emission requirements.

- Durability

-

Regular spherical particles with acid, alkali, and high-temperature resistance, boasting over 2000 regeneration cycles.

- Purity Assurance

-

Synthetic styrene structure devoid of metal impurities prevents catalytic polymerization or combustion of unsaturated organics in pores.

- Effectiveness

-

Achieves over 99.5% removal rate for non-polar and weakly polar VOCs, ensuring emission compliance.

- Security

-

Exhibits excellent hydrophobicity, eliminating the need for dry adsorption and preventing sustained heating due to adsorption exotherm.

- Sustainability

-

Extended life cycle with no need for complete replacement and zero solid waste generation. Annual replenishment of approximately 5%.

- Economic Value

-

Enables recovery of solvents with recycling value, delivering economic benefits.

Suitable Volatile Gases for Resin Adsorption Technology:

Our resin adsorption technology caters to a wide array of non-polar solvents, including alkanes, alcohol ethers, chlorinated hydrocarbons, ketones, aromatic hydrocarbons, esters, and organic amines.

Industries Benefiting from Resin Adsorption for VOCs Treatment:

Beyond emission compliance, Glorinda's adsorption technology ensures the efficient recovery of organic volatiles in waste gas, boasting a recovery rate exceeding 99%.

Our Comprehensive Services and Support:

- On-site test and demonstration

- Design of treatment plan

- Supply of adsorption resins

- One-stop-shop EPC solution package (system design, adsorption resins, system engineering, installation, and debugging, staff training)

- Professional technical support and maintenance

Glorinda Company, a trailblazer in environmental solutions, has successfully collaborated on 100+ projects spanning pharmaceuticals, chemicals, and related industries.